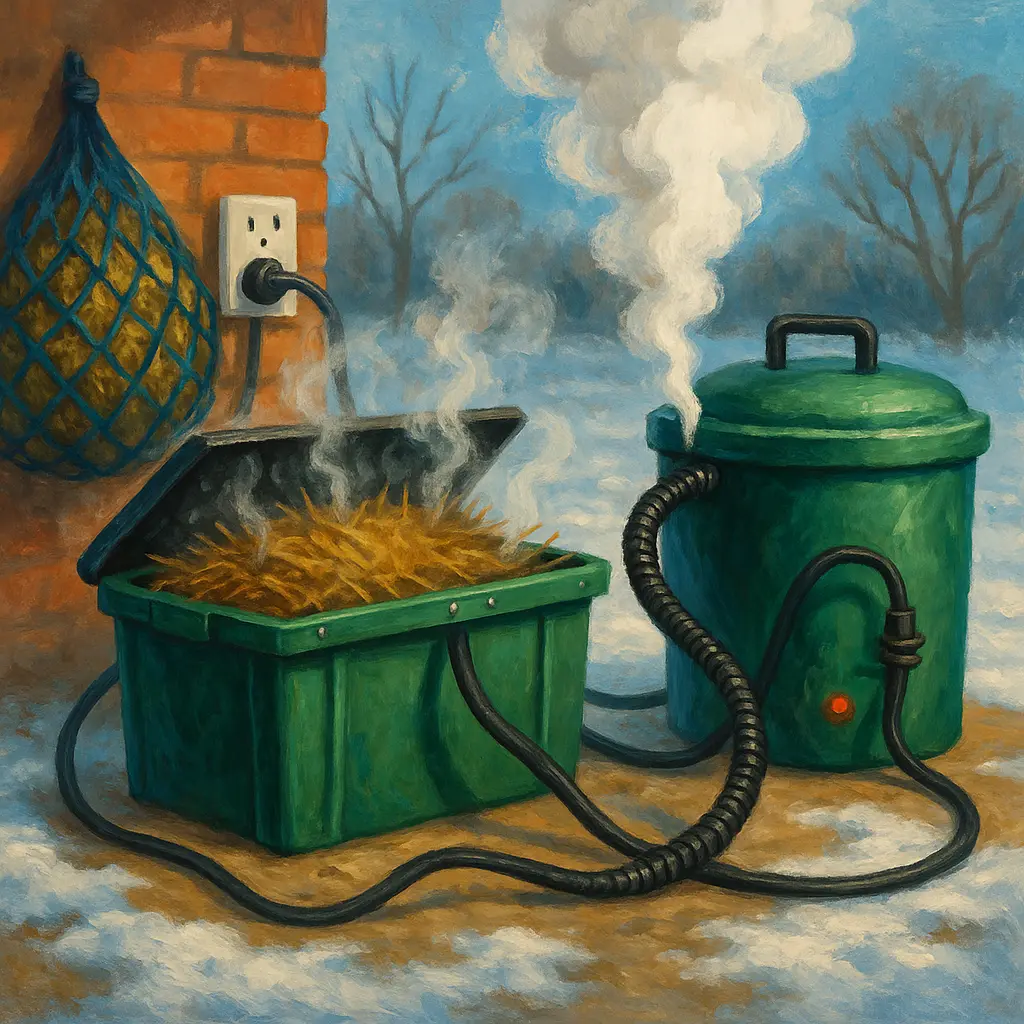

When your horse’s breathing and performance depend on dust-free forage, a Haygain steamer has to work first time, every time — even in a frosty UK yard. This guide gives you clear, practical steps to power, run and troubleshoot your unit through winter and beyond.

Key takeaway: In the UK, most Haygain steaming issues come down to three things — power supply, freezing hoses/manifolds, or limescale. Get the power right, keep components warm and drained, and descale regularly to keep cycles at 50–60 minutes (up to 1.5 hours in cold weather).

Power & setup: what your Haygain really needs

HG ONE needs 1.5 kW, HG 600 (post-May 2022) needs 2.3 kW, and HG 2000 needs 2.75 kW — ideally each on a separate circuit for dependable performance. If your electrics trip, check supply capacity and cable quality before assuming a fault.

Haygain steamers draw significant, sustained power, so treat them like a high-load appliance. Avoid long, thin extension leads that drop voltage and overheat; if you must extend, use a heavy-duty outdoor-rated cable and keep it fully uncoiled. The HG 600 typically reaches temperature in 20–40 minutes before its full cycle begins, and any shortage of power will delay that warm-up or cause intermittent steaming.

For everyday convenience, use the timer plug supplied with Haygain to automate steaming slots. On busy livery yards, dedicated circuits prevent nuisance tripping when other high-load kit (kettles, dryers, clippers) is running. If you’re unsure about your circuit capacity, a qualified electrician can advise on load and socket condition — a worthwhile check before winter.

How long to steam hay through the seasons

Most cycles take 50–60 minutes, extending to about 1.5 hours in cold UK conditions when water, hay and ambient temperatures are low. In winter, pre-warming the hose/boiler and clearing ice can prevent long, frustrating delays.

Steaming time varies with:

- Starting water temperature (cold taps slow warm-up)

- Ambient temperature (below 0°C adds warm-up time)

- Power supply (voltage drop or shared circuits lengthen cycles)

- Hay density and quantity (looser, evenly packed hay steams faster and more evenly)

The HG 600 commonly reaches temperature in 20–40 minutes, then runs its steaming phase. In sub-zero weather, expect longer or run a quick pre-heat. If your hay or chest has been stored outside, bring components inside to reduce ice formation and shorten the total cycle.

Quick tip: In freezing spells, connect the hose to the boiler only and heat for 15–20 minutes before loading hay. If there’s no steam at that point, the hose is likely frozen — clear it (see next section) before you waste time on a full bale.

Winter troubleshooting: clear freezing fast

If you see no steam after 15–20 minutes in freezing conditions, your hose or manifolds are likely frozen; clear them with hot water and gentle squeezing, then re-test.

Use this quick, no-tools winter drill:

- Test the hose alone: Connect the hose to the boiler only and heat for 15–20 minutes. If no steam appears, switch off and let the boiler cool for 5 minutes. Immerse the hose (especially bends) in hot water and gently squeeze along its length to shift ice. Reconnect and re-test.

- Check the chest and manifolds empty: Connect the hose to an empty chest and heat 15–20 minutes. If spikes/manifolds don’t emit steam, switch off, allow cooling time, then pour boiling water over the manifolds and squeeze the small hoses to melt internal ice.

- Drain after every use: Disconnect the hose from the chest, tip the chest so condensation drains via the brass connector, and store the hose straight (not coiled tight) in a warm tack room.

- Store warm between cycles: Keep the steam generator indoors or in a heated tack room to avoid cold-soak and repeated icing.

“When not in use, keep the steam boiler inside in a warm place (such as a heated tack room). After use, allow to cool, then disconnect hose from steam chest and drain hose.” — Haygain Troubleshooting Guide

Pro tip: In UK cold snaps, clear ice before you load hay. Running the boiler against a frozen line just vents pressure and wastes time.

Descale on schedule to prevent breakdowns

Regular descaling is essential in UK hard-water areas; always let the boiler cool (minimum 5 minutes before refilling and 30+ minutes before descaling) and use Haygain Descaler as directed. Limescale lengthens cycles, causes cut-outs and can void parts of the warranty.

Haygain units ship with descaler packs — build them into your routine, especially if you notice any of the following:

- Audible buzzing or clicking from the boiler

- Cycling that’s consistently longer than 60 minutes (outside of cold snaps)

- Electrics tripping once the element is hot

- Reduced or uneven steam output

Schedule descaling frequency to your water hardness; many UK regions are hard or very hard, so more frequent treatment is prudent. If in doubt, check your water provider’s hardness rating and descale accordingly. Always switch off and unplug before maintenance, and never pour cold water onto a hot element. Allow at least 5 minutes’ cool-down before refilling to prevent thermal shock and element damage.

“The Steam Generator needs servicing and the Thermofuse needs replacing. Always descale the Steam Generator once the Thermofuse has been changed.” — HG2000 User Manual

Quick tip: Keep a small calendar by the boiler and tick off descaling dates. Preventive care is cheaper than a new element and far less disruptive to your horse’s routine.

Fixing no steam, tripping electrics and pressure vents

No steam usually means ice or limescale; tripping electrics points to limited power supply or a scaled element; steam from the filler cap indicates a blocked/frozen hose or a dirty pressure valve.

Work through issues methodically:

- No steam output: In winter, suspect frozen hose/manifolds first (see winter troubleshooting). Otherwise, descale and re-test. Confirm the unit is on a suitable circuit — underpowered sockets or flimsy leads can prevent full heat-up.

- Electrics tripping or won’t turn on: Check for limescale build-up on the element and descale. Verify you’re using a robust power supply with a heavy-duty adaptor if extending. Avoid dry boiling — always ensure adequate water in the boiler.

- Steam escaping from the filler cap/valve: Detach the hose and test the boiler alone. If it steams freely, the line or chest is blocked or frozen. Clean the pressure valve if dirty and flush the hose using a flushing adaptor or hot water.

If a component has failed or a boiler is damaged, spare parts and repairs are handled directly by Haygain’s specialised customer support team in the UK. From elements and seals to hoses and manifolds, they can advise on the correct part and arrange service when needed.

Pro tip: Keep a small kit beside your steamer: kettle, bucket for hot water, gloves, and a spare timer plug. Rapid response to icing and a reliable timer keep your yard routine on track.

Balance the HG2000 manifolds for even steaming

If one manifold isn’t steaming on an HG2000, restrict flow to the side that is steaming or squeeze the hoses to force steam through and clear excess condensation. Always test on an empty chest first so you can see the spikes venting.

Uneven output is almost always condensation or a partial blockage rather than a serious fault:

- Run the boiler with an empty chest for 15–20 minutes and watch the spikes/manifolds.

- If one side lags, gently pinch or briefly restrict the hose on the flowing side to build back-pressure and drive steam into the cool side.

- Squeeze along the lagging side’s small hoses to move trapped water; pour boiling water if needed in freezing weather.

“If steam is not coming from all Spikes, restrict the Hose that leads… release the main pipe and the back pressure of steam should force the excess water/condensation out.” — HG2000 User Manual

Build a reliable winter steaming routine

Store the boiler warm, drain hoses after every use, and automate cycles with a timer plug to keep steamed hay consistent all winter. A simple, repeatable routine prevents 90% of cold-weather hiccups.

Follow this workflow on UK yards:

- Pre-warm: Keep the steam generator in a heated tack room; in freezing spells, pre-heat the hose connected to the boiler only for 15–20 minutes.

- Load smart: Shake hay out lightly in the chest for even penetration; don’t overpack.

- Steam: Allow 50–60 minutes in normal conditions; up to 1.5 hours in cold weather. Use the timer plug to start cycles while you muck out or ride.

- Drain & store: After switching off and cooling, disconnect the hose from the chest, tip to drain condensation via the brass connector, and store the hose straight and warm.

- Descale: Build descaling into your weekly or monthly routine based on water hardness, and always cool the boiler properly before refilling.

For tidy yard management after steaming, bale bags and non-shrink hay nets keep steamed forage clean and easy to carry on wet, muddy days. When your horse is standing around post-ride while you steam, ensure they’re comfortable and dry in the right rug for the weather. Explore breathable, waterproof winter turnout rugs and cosy stable rugs from trusted brands for consistent comfort between sessions.

At Just Horse Riders, we also see winter skin and coat care benefit from consistent hygiene. Regular grooming helps manage grease build-up from steamy conditions — stock up on yard-proof brushes and mitts in our grooming collection. For horses needing extra respiratory or immune support while you optimise forage, browse targeted options in our horse supplements range.

Dark evenings demand better visibility on busy yards and lanes while your steamer runs — add reflective layers from our hi-vis rider collection. And for legs coping with slippy gateways and extra standing time, protective wraps from our horse boots and bandages collection can help reduce knocks and scrapes.

Quick tip: If you’re refreshing yard kit for winter, check our rotating offers in the Secret Tack Room clearance — perfect for picking up spares and backups that keep your steaming routine moving.

FAQs

How do I set up my Haygain steamer correctly the first time?

Connect the steam generator, chest and hose; fill the boiler with water and the chest with hay; plug into a suitable power source; then switch to steam. Haygain includes a clear manual with step-by-step guidance for each model.

“Haygain Hay Steamers arrive with a manual of easy-to-follow instructions… To steam, simply connect the steam generator, chest and hose. Fill boiler with water, fill the chest with hay, plug the boiler into the power source, then set its switch to steam.” — Haygain FAQs

How long should I steam hay in UK winter?

Plan for 50–60 minutes, but allow up to 1.5 hours when the water, hay and ambient temperatures are very cold. In freezing conditions, warm the hose for 15–20 minutes before loading hay and clear any ice first.

Why has my Haygain stopped steaming?

In winter, the most common cause is a frozen hose or manifold; test and clear with hot water and gentle squeezing. Otherwise, descale the boiler and check your power supply is adequate and on a dedicated circuit.

My electrics trip when I start steaming — what should I check?

Confirm your model’s power requirement (HG ONE 1.5 kW, HG 600 2.3 kW, HG 2000 2.75 kW) and use a robust circuit with heavy-duty cable if needed. Limescale on the element can also cause cut-outs — descale and re-test.

Steam is escaping from the filler cap — what does that mean?

That typically indicates a blockage or freeze in the hose or chest, or a dirty pressure valve. Detach components and test the boiler alone; clear ice, flush or clean the valve, then reassemble and test again.

Where can I get Haygain spare parts or repairs in the UK?

Contact Haygain’s specialised customer support team directly. They supply official spare parts (hoses, manifolds, elements, seals) and arrange repairs, including boiler servicing.

What’s the safest way to refill and descale?

Never pour cold water onto a hot element. After steaming, switch off and allow at least 5 minutes before refilling, and 30+ minutes before descaling. Use Haygain Descaler as directed, especially in hard-water areas.

Keep your steamer warm, your routine consistent and your power supply solid, and you’ll deliver clean, comfortable forage for your horse all year. If you need yard-ready kit to make winter steaming smoother, we’re here to help with reliable turnout rugs, practical grooming gear, and thoughtful savings in our Secret Tack Room.